In today's highly competitive market environment, product appearance and brand identity play a vital role. Especially in the fields of clothing, washing and chemical industry, high-quality No. 8 leather label and washing label can not only highlight the brand image of the enterprise, but also enhance the confidence of consumers. Let's take a closer look at the importance of these key elements and the secrets behind them.

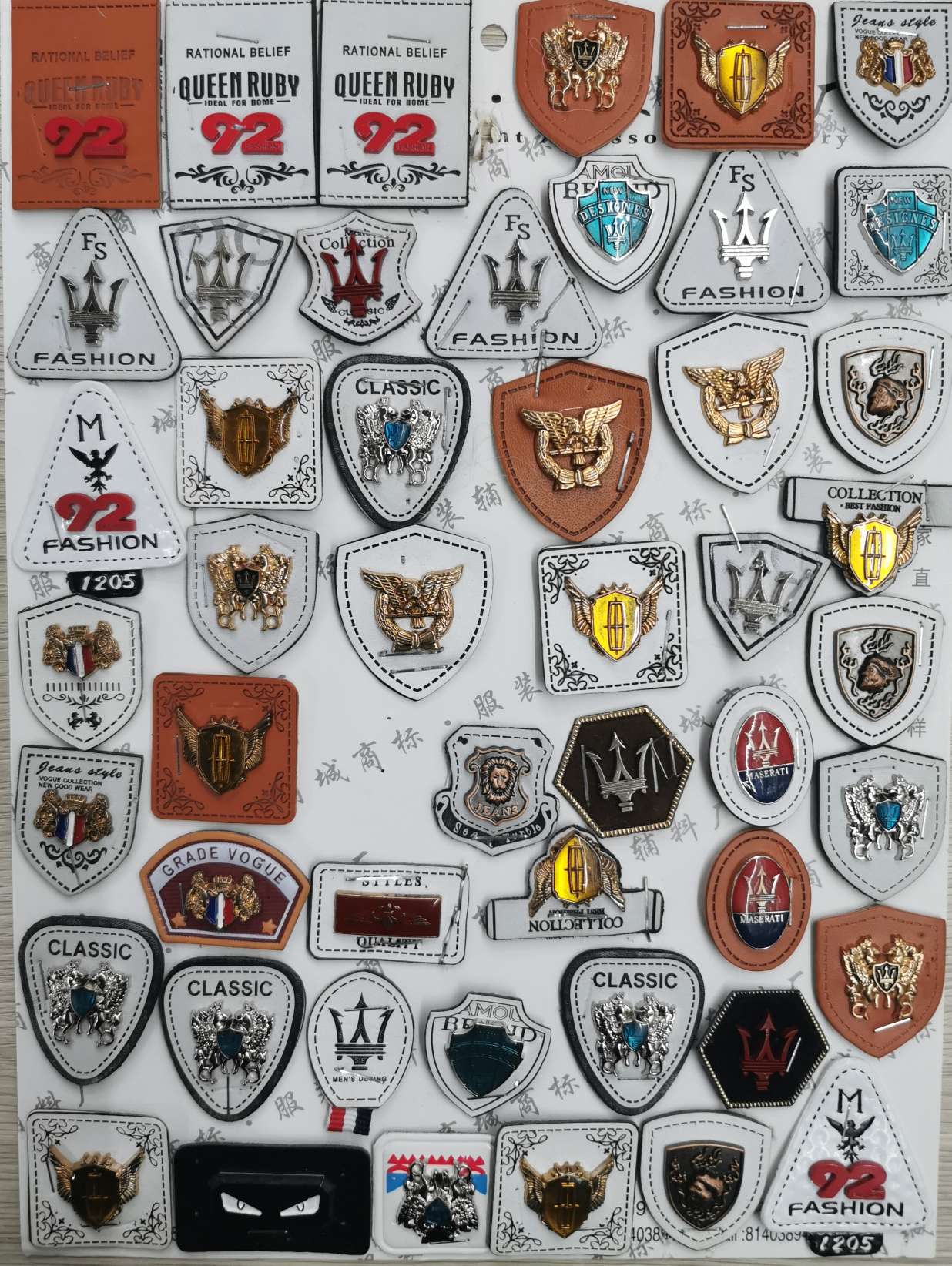

Understand the unique advantages of No. 8 skin standard and its wide range of applications

No. 8 leather label is a very textured brand logo form, usually made of high-grade leather materials. Compared with ordinary printed matter, it has stronger durability and higher-end touch experience, so it is widely used in luxury packaging, high-end clothing tags and industrial equipment nameplates and other fields. Whether it is small batch trial production or mass production, No. 8 leather standard can always meet the diverse needs of customers.

How to enhance brand image and market competitiveness through personalized customization

With the increasing demand for product quality, relying solely on basic functionality is no longer enough to win market share. And personalized customized service has become one of the important means for enterprises to stand out. For example, you can choose different font styles, color schemes and even special processes (such as bronzing and embossing) according to your brand tonality, so that each product is unique and difficult to imitate and copy.

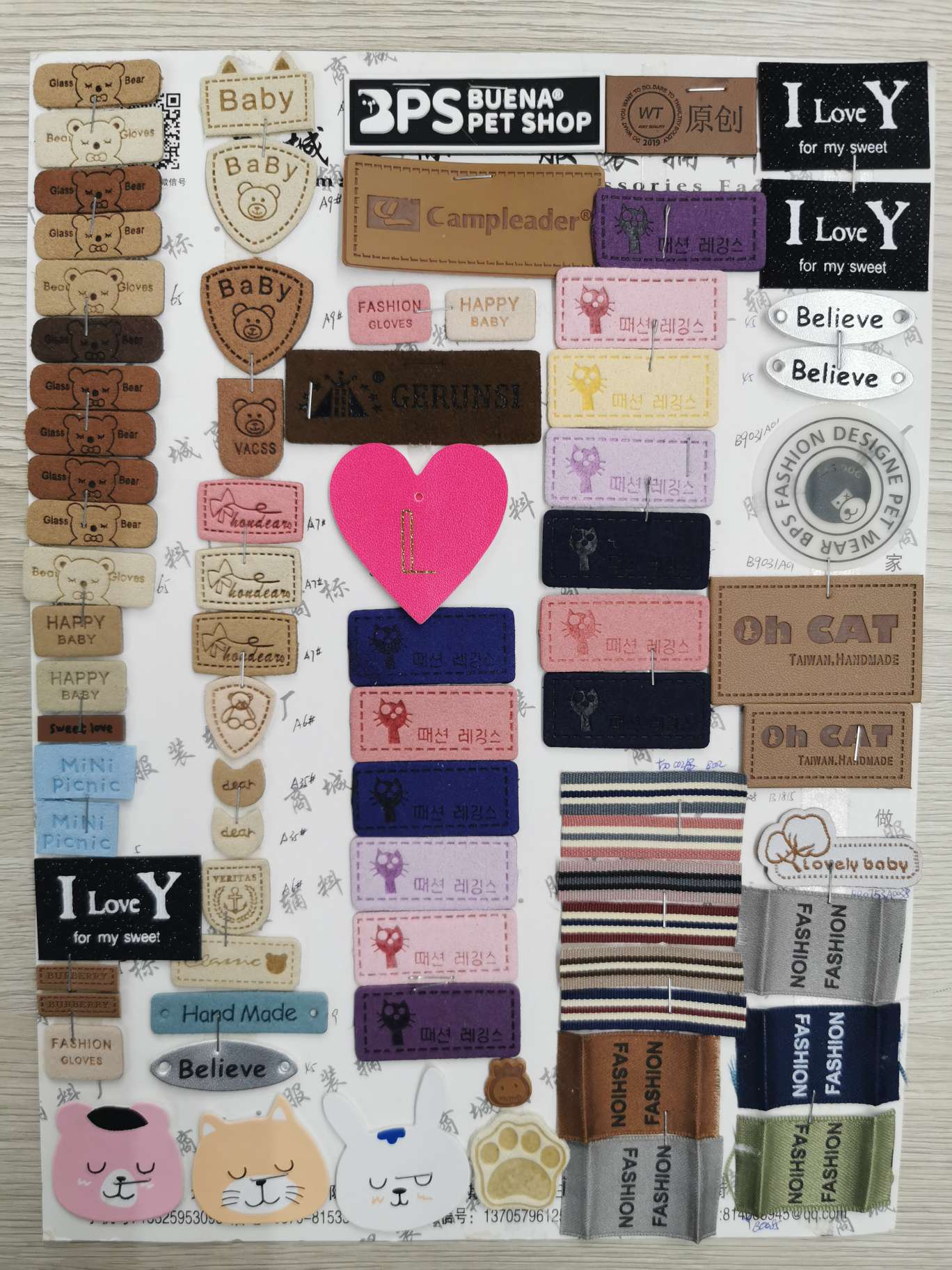

Interpreting the key elements of high-quality washing labels: materials, design and functions.

In addition to the No. 8 leather label, the special label for the washing chemical industry can not be ignored. This kind of label not only needs to withstand the test of high temperature and high pressure cleaning process, but also must ensure that the information is clear and recognizable after long-term use. For this reason, we especially recommend the use of water-and oil-resistant PVC film or PET substrate with UV curing ink printing technology to complete the manufacturing process-both environmentally friendly and safe.

Case Study: The Secret Behind the Logo of a Successful Brand

Many internationally renowned brands are able to take the lead among their competitors in large part because of their attention to detail. For example, a well-known sneaker manufacturer once switched to a new generation of synthetic fiber woven marks, which are softer, lighter but stronger, because it found that traditional metal badges are easy to cause wear and tear. Another daily chemical group has achieved the purpose of rapid identification and enhanced the overall coherence and consistency by giving each of its series of products a unified and color-focused theme.

Choosing the right supplier: a full range of services from in stock supply to quick response

When you are ready to purchase related materials, please be sure to give priority to those professional manufacturers who can provide comprehensive solutions. On the one hand, they will reserve sufficient regular styles for instant pick-up to cope with emergency orders. On the other hand, with years of accumulated experience, you can also tailor the most suitable combination of technical parameters for specific application scenarios, thus greatly shortening the development cycle and reducing the cost investment ratio. In addition, a good after-sales service system is also one of the core indicators to measure whether a qualified partner is trustworthy-only companies that are willing to listen to customers' voices and continuously improve their shortcomings can achieve a win-win situation and lasting development!

Details determine success or failure: pay attention to every link in the customization process

No matter how exquisite the design concept is, if it is not implemented in place, it will fall short. Therefore, before the formal start of the project implementation, it is necessary to fully communicate and clarify the specific numerical provisions of various specifications and standards, including but not limited to the allowable value of the size error range, the control limit of surface roughness grade, etc. At the same time, we should also pay close attention to the performance of the proofing test phase and adjust it in time until it is completely satisfied before it can be officially put into production and popularized on a large scale.

Future Trends: Exploring New Opportunities for the Label Industry in the Digital Age

With the continuous progress of science and technology, innovative achievements have also injected new vitality into traditional industries. In particular, the intelligent RFID radio frequency identification technology and AR augmented reality interaction mode that have emerged in recent years have begun to gradually penetrate into our daily life, and have shown broad application prospects and potentials. They are waiting for excavation, development, utilization, greater value creation, better tomorrow, meeting challenges, creating brilliant achievements, and dreams to come true. The road to freedom and freedom, freedom, happiness, happiness and happiness are endless. The scenery of the journey is unique and unforgettable.