Every brand has a story — but few realize it begins not with a logo on a storefront or a social media post, but with a quiet moment: the first time a customer slips their fingers inside a garment and feels something unexpected. Smooth yet textured. Subtle, yet unmistakable. That’s the power of a well-crafted label — not just an instruction tag, but a tactile whisper of identity.

When Details Speak Louder Than Logos

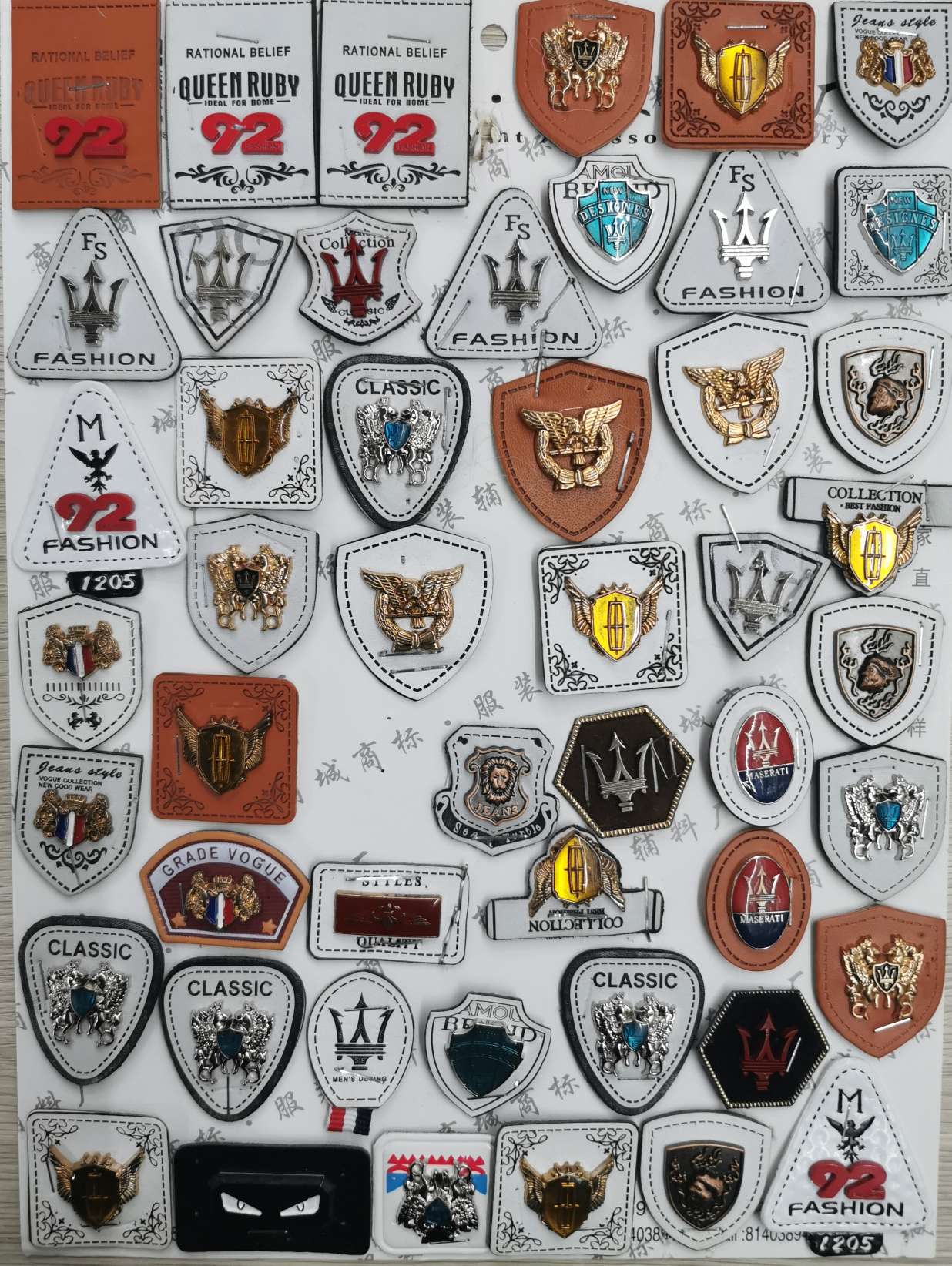

In today’s crowded marketplace, consumers don’t just buy products — they buy meaning. And increasingly, that meaning is found in details too small to shout, but powerful enough to resonate. A custom woven leather label isn’t merely functional; it’s emotional design. It tells the wearer: *This was made with care. This brand values craft.*

Imagine a customer unfolding a hand-stitched leather wallet. Before they even see the brand name, their thumb brushes against a soft, finely woven label. No loud printing, no plastic sheen — just understated texture and precision. In that instant, perception shifts. Luxury isn’t declared; it’s discovered.

Why No. 8? The Quiet Perfection of Proportion

The magic of the No. 8 size lies in its balance — a harmonious 25mm width that speaks clearly without dominating. It's large enough to carry essential care instructions or a brand name legibly, yet narrow enough to sit discreetly along a side seam or collar. Whether embedded in a lightweight linen shirt, a baby onesie, or a structured tote bag, the No. 8 label integrates seamlessly into the design language of premium goods.

This dimension has become a favorite among independent designers and heritage brands alike. For minimalist fashion labels, it offers clean space for elegant typography. For artisanal leather workshops, it provides room for dual-language care symbols and subtle branding. Its versatility makes it not just a standard — but a silent standard-bearer.

The Art Woven Into Every Thread

Beneath the surface of each No. 8 label is a journey of craftsmanship. It starts with selecting supple, full-grain leather substrates and premium polyester or cotton yarns — materials chosen for both longevity and comfort against skin. Then comes the loom: where digital precision meets artisan technique.

High-density weaving ensures every character remains crisp, even at half a centimeter in height. Serif fonts retain their grace; block letters hold their edge. The result? A label that doesn’t degrade after washes or wear, but instead develops a gentle patina — like the product it represents, aging with dignity.

More Than a Name — A Signature in Fiber

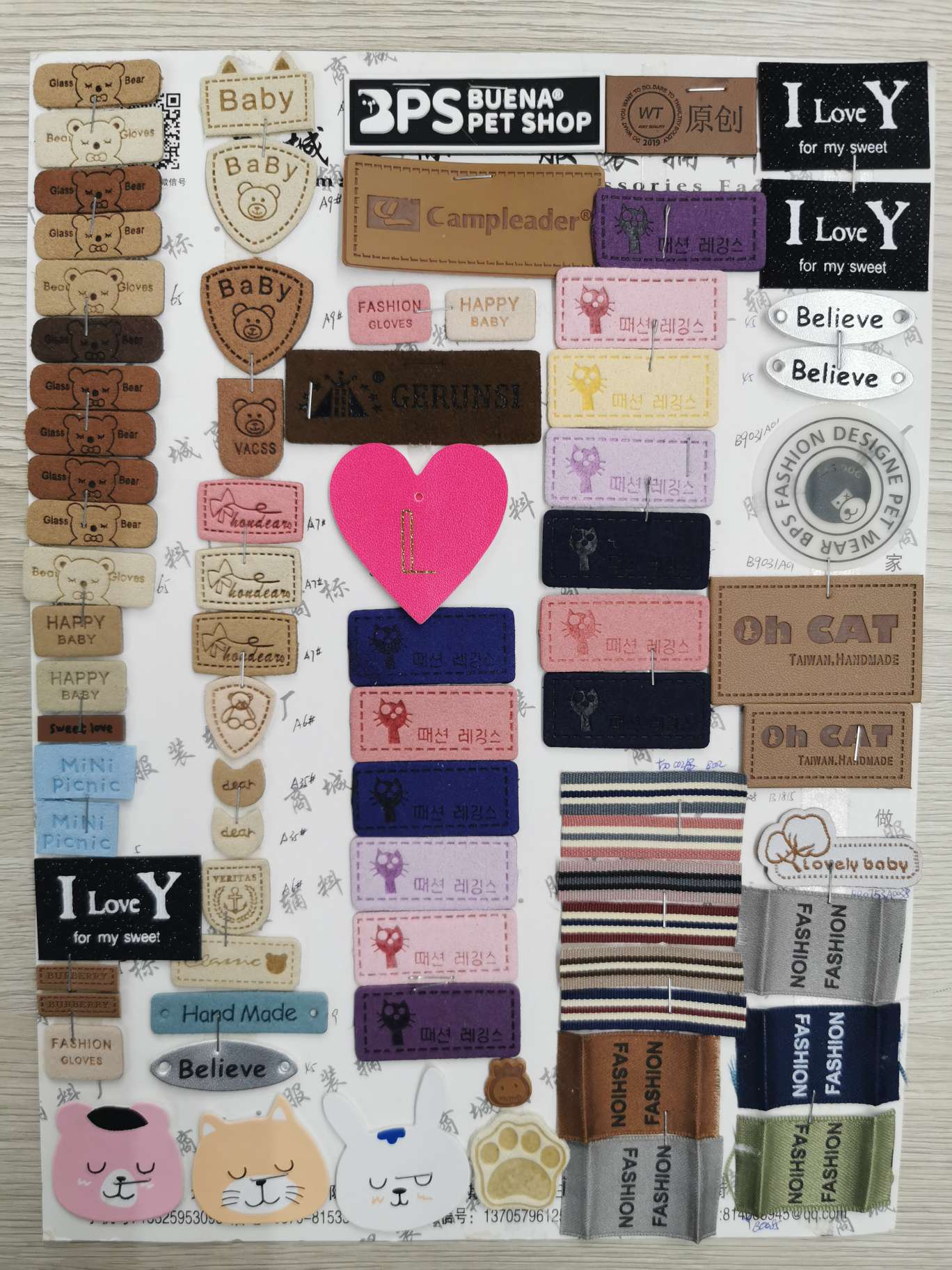

Your brand isn’t one-dimensional, so why should your label be? With our customization suite, the No. 8 leather label becomes a canvas. Choose from contrast edging in signature brand colors, diagonal twill backs for added depth, or reverse-weave techniques that reveal hidden messages when flipped.

One emerging designer recently embedded a micro-motto — “Wear Your Values” — in a tone-on-tone weave only visible under direct light. Another luxury pet accessory brand used mirrored embroidery so the logo appears correct whether viewed from front or back. These aren’t gimmicks; they’re layered expressions of identity, felt before they’re seen.

Small Batches, Big Impact — Without the Wait

Gone are the days when custom labels meant MOQs in the thousands and lead times stretching into months. Thanks to agile OEM/ODM support, even startups can access high-end woven leather labeling with minimum orders as low as 500 units. Rapid prototyping allows you to test designs in under 48 hours, and full production can ship in as little as seven days — all without sacrificing quality.

We recently collaborated with a new eco-conscious loungewear line launching at a pop-up event. From concept sketch to final sew-in labels, the entire process took one week. Their debut collection featured earth-toned labels with recycled thread — a detail guests remembered more than the packaging.

Speed Meets Consistency — The Supply Chain Advantage

Fast doesn’t mean flawed. Our integrated supply model combines standardized dye lots, automated tension control during weaving, and edge-sealing technology to ensure every roll arrives with uniform color, sharp borders, and fray-resistant ends. Whether you order 500 or 50,000, the label sewn into your first jacket will match the last — batch after batch.

Where Else Belong Do These Labels?

While born in fashion, the No. 8 woven leather label has found poetic second lives. Specialty tea brands use them as elegant seal tags on limited-edition tins. Independent publishers attach them as cloth waistbands on numbered book releases. Perfume houses dangle them from wax-sealed candle jars, turning scent into ceremony.

Each application transforms utility into ritual. A tea drinker pauses before brewing, reading the woven origin story. A reader runs a finger over the textured band on a novel’s spine. These moments matter — and they begin with a thread.

The Future Is Woven — Sustainably and Smartly

What’s next? We’re pioneering plant-tanned leather options sourced from eco-certified tanneries, reducing environmental impact while preserving rich texture. Simultaneously, we’re exploring integration with micro-RFID threads — invisible tech that lets customers scan a label to verify authenticity, trace production history, or access styling tips.

The label of tomorrow won’t just identify — it will interact. But its soul will remain unchanged: a quiet emblem of pride, stitched into every product that dares to stand out by staying true.

Because in the end, the most memorable brands aren’t the loudest. They’re the ones you feel before you hear.